The high temperature and hot environment is an important test for the use of the inkjet printing equipment of the piezoelectric uv printer. The high temperature environment not only affects the normal inkjet printing of the photo machine, but also affects the electronic board accessories related to the photo machine, inkjet printing operation, related Print media, image color, etc. will all have a certain impact on use.

In the high-temperature environment where the printer is used, attention should be paid to cooling the space where the printer is used, and the temperature of the working environment of the printer should not exceed 40 degrees. The printer will stop working under high temperature and affect the operation. Especially when the piezoelectric uv printer is in the long-term uninterrupted printing working condition, the high temperature will easily cause the relevant control board of the photo machine to appear high temperature, which will affect the printing performance. The impact of transmission, the slowdown of printing speed, and even other serious damage to chips, electronic components, circuits, etc.

In addition, if the working environment temperature of the photo machine is too high or too low, it will also cause the nozzle of the photo machine to be disconnected, because the ink used in the photo machine has a specified working environment index, and the viscosity index of the ink will change with the ambient temperature. The working voltage of the nozzle corresponding to the different viscosity will also change accordingly, otherwise it will cause the instability of the ink jetting of the nozzle hole, and the phenomenon of disconnection and ink breakage will easily occur. When the temperature is high, the viscosity of the ink decreases. At this time, the operating voltage of the nozzle should be appropriately reduced, otherwise it is easy to form air bubbles inside the ink pipe, causing no ink to be ejected from the nozzle hole, resulting in white lines on the screen, and forming a break in the inkjet printing of the photo machine. line phenomenon.

Therefore, in the high-temperature working environment of the photo machine in summer, it is necessary to properly ventilate and cool down the space used by the photo machine. The ventilation of the working space of the photo machine is directly related to the temperature of the space, because in a poorly ventilated working space, the heat emitted by the machine during operation and the accumulation of room temperature will easily lead to the overall high room temperature, in summer indoor and outdoor, the temperature is relatively high. If the indoor space is not well ventilated and the temperature cannot be dissipated, the machine will be easily affected by the temperature and cause related failures, which will affect the normal inkjet printing of the photo machine; In an unventilated working environment, coupled with a high-temperature indoor space, it is easy to produce a strong ink smell, and it is easy to produce an uncomfortable feeling for the operator. It is very necessary to give the photo machine a cool working environment in the hot summer.

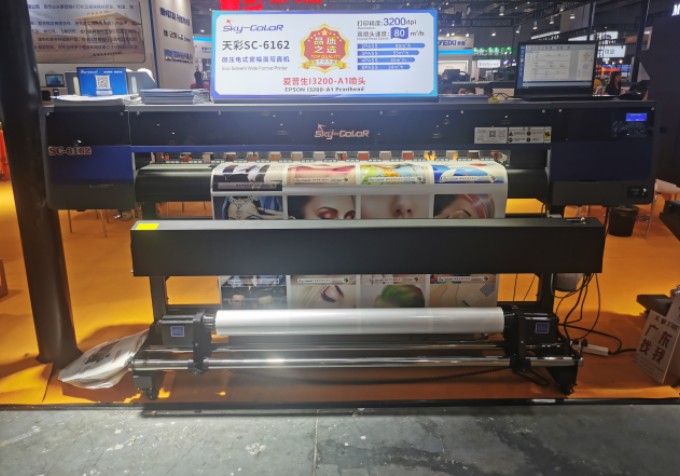

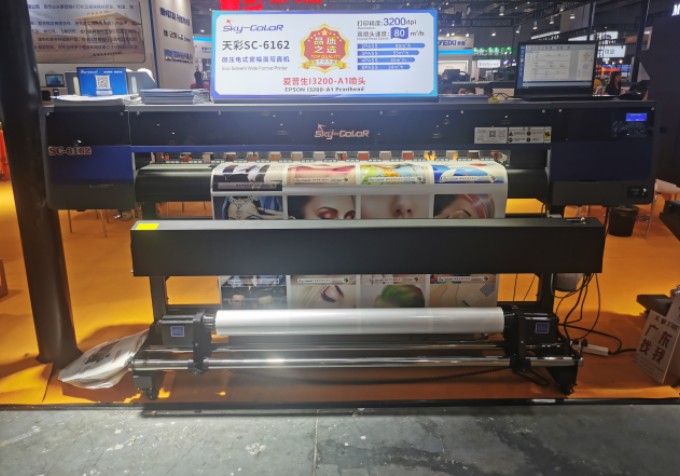

Zhengzhou New Century Digital Technology Co., Ltd (Skycolor UV Printer:

www.skycoloruv.com) is a professional high-tech enterprise engaged in R&D, production and sale of skycolor uv flatbed printer,skycolor uv roll to roll printer and related consumables.

Over the years,company has accumulated rich experience in digital uv printing field and gathered a batch of employees with professional skills. With high product quality and standardized service system,company has won high reputation from global market and trust of cooperated units.